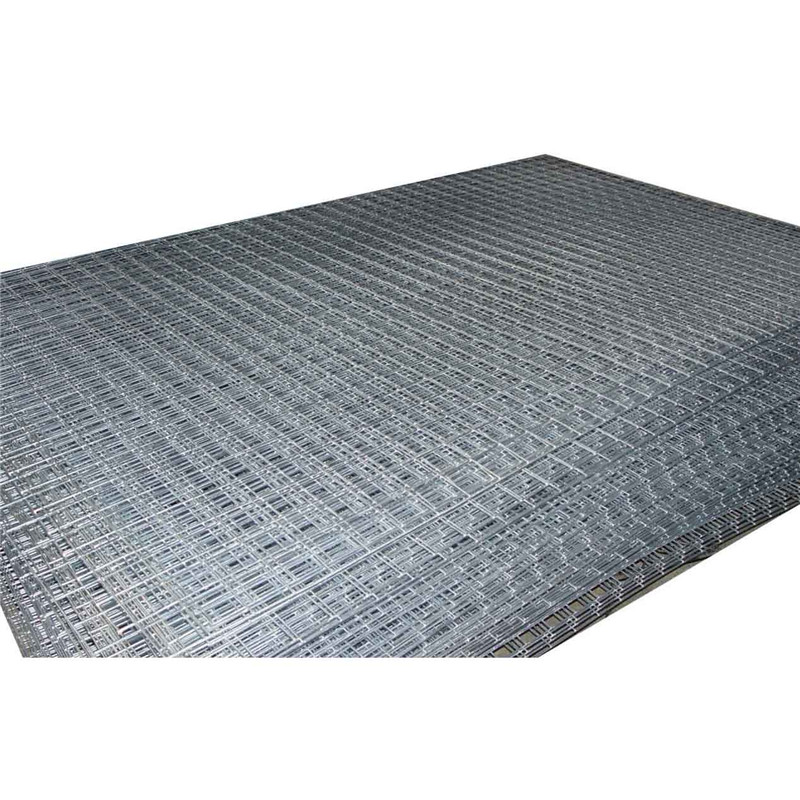

I-WELDED WIRE MESH (Isetshenziswa ekusetshenzisweni kokusekelwa komhlabathi)

IZICI EZISHISELEKILE ZEMISH

● I-Welded Wire Mesh yenziwe ngocingo olumnyama noma lukathayela

● Ibanga elihlukile lezintambo ezitholakalayo ukuhlangabezana nezipesheli zekhasimende ezidingekayo

● Usayizi ohlukile wemeshi otholakalayo

● I-diameter ehlukene yenduku yocingo etholakalayo

● Ukwakhiwa kwemeshi kungenziwa ukuze kuhlangabezane nezidingo ezahlukene

INKCAZELO YEZINDAKA EZINGCIMBI EZISHISHILE

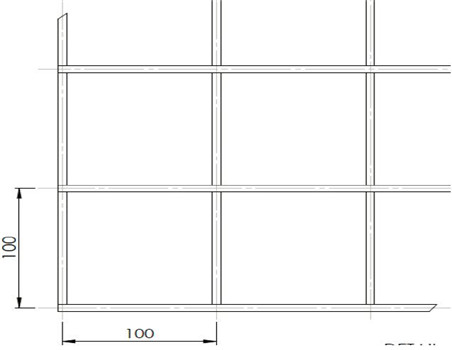

| I-SPEC. | UHLOBO LWENWAMBO | WIRE DIA | UKWENZA ISIKHALA | CHA.VALIWE | LENGTH | QEDA | ||||||

| SIZE (mm) | mm | mm | PCS | mm | ||||||||

| 3000×1700 | Intambo Emide | 5.6 | 100 | 18 | 3006 | Gal.Intambo | ||||||

| Cross Wire | 5.6 | 100 | 31 | 2406 | Gal.Intambo | |||||||

| 3000×2400 | Intambo Emide | 5.6 | 100 | 25 | 3006 | Gal.Intambo | ||||||

| Cross Wire | 5.6 | 100 | 31 | 2406 | Gal.Intambo | |||||||

| 3000×2400 | Intambo Emide | 5.0 | 100 | 25 | 3005 | Gal.Intambo | ||||||

| Cross Wire | 5.0 | 100 | 31 | 2405 | Gal.Intambo | |||||||

| 3000×2400 | Intambo Emide | 4.95 | 100 | 25 | 3005 | Gal.Intambo | ||||||

| Cross Wire | 4.95 | 100 | 31 | 2405 | Gal.Intambo | |||||||

Qaphela: Isikhala socingo singenziwa nge-25×25, 50×50, 50×75, 75×75, izidingo ezikhethekile zingaxoxisana nazo.

ABALINGISI ABASHISHILE LWEMESHI

● Okuncane.Amandla Okuqina Wocingo: 400Mpa

● Ubukhulu.Amandla Okuqina Wocingo: 600Mpa

● Okuncane.I-Weld Shear: 9.3KN

● Okuncane.I-Torque Value: 18Nm

● Okuncane.Ukungena kwe-Welding: 10%

● Ngokuvamile isilinganiso se-Zinc Coating: 100g-275g/m²

Njengengxenye eyinhloko yokumboza nokuvikela, i-mesh isetshenziswa kabanzi kumaphrojekthi wokwesekwa komhlaba.Ngendawo yokushisela enezikhala ezizenzakalelayo, i-TRM ingahlinzeka ngamathani angamakhulu namakhulu e-welding mesh ngesikhathi esifushane kakhulu.Isikhungo sethu se-mesh sisebenza kahle kakhulu esingaphakela izintambo ezinde neziphambanayo ngokuzenzakalelayo futhi sicindezele ukushisela lonke ishidi lenetha ngesikhathi esisodwa, lokho kusenza sithole izindleko eziphansi kakhulu zokusebenza futhi ezingahlinzeka ngamanani amanani aphansi kakhulu.Ngaleso sikhathi, isistimu yokulawula ikhwalithi ye-TRM ingakwazi ukulawula ikhwalithi yenqubo ngayinye kahle kakhulu futhi amarekhodi okulandelela azodlula kuwo wonke ukukhiqizwa kusukela ezintweni ezingavuthiwe kuye kuma-mesh wokugcina agcwele, angaqinisekisa ukuthi yonke i-mesh isebenza kahle.Futhi singenza ukuhlolwa kokudonsa kwama-welds njengezidingo zekhasimende, futhi umbiko wokuhlola wokudonsa uzokhishwa kanye neqoqo ngalinye le-Mesh entsha.